Hardwood lippings can be easily bonded to door blanks using WOODS RF presses. Suitable for use with PVA or resin type adhesives, three types of machine are available to carry out this operation;

The SE (Single Edge) range of presses are designed to clamp and bond one lipping to one edge at a time, fitted with a turning support arm to assist the operator in rotating the door. With a range of press lengths available from 1200mm to 3000mm, the SEP is capable of bonding many different lipping applications from 12mm MDF panels up to 63mm 2 hour fire check door blanks producing a structurally stable joint in as little as 45 seconds. This cost effective and simple to use machine is ideally suited to low/medium production requirements. |

|

The HTP (Hydraulic Tray Press) is a machine designed for many different applications which door lipping is one of them. The machine has two pressing trays which alternate between the pressing area and the loading position, this enures the operator has no "waiting" time whilst the glue is curing.

With the capability of lipping up to four sides of the door blank in a single operation and a range of options such as an opening end to allow for oversize panels, this is an ideal and versatile machine for medium to high production. |

|

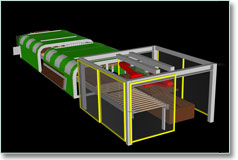

The TELP (Totally Enclosed Lipping Process) Door Line is a completely automated door lipping production line, designed to lip and trim all four sides of veneered or laminate door blanks, at a constant rate of 40 doors per hour, regardless of the mix of sizes. When fitted with the optional output de-stacker, the machine is truly a single-man operation.

The TELP is designed around the concept that the door blank moving through the machine acts as the size adjusting mechanism. This removes any need for operator input for size adjustment or complex automatic dimensioning mechanisms. Fitted with NORDSON glue sprayers, end trimmers, pre-milling cutters and large capacity lipping hoppers, the TELP provides users with a complete door lipping solution.

|

|

|